Unlocking Huge Power Savings: The Star-Delta Connection of 3-Phase Motors

Electric motors are the workhorses of modern industry, powering everything from pumps and fans to conveyor belts and manufacturing equipment. But these powerhouses can also be energy guzzlers. Optimizing their operation is crucial for reducing energy consumption and operational costs. One of the most effective methods for achieving significant power savings with 3-phase motors is the star-delta starter connection. This article delves into the mechanics, benefits, and applications of this widely used technique.

Understanding the Star-Delta Connection: A Primer

The star-delta connection is a starting method for 3-phase induction motors, designed to reduce the inrush current during motor startup. This inrush current, often 5-7 times the motor’s rated current, can cause several problems, including:

- Voltage dips: Fluctuations in the power supply that can affect other connected equipment.

- Excessive heat: Generated within the motor windings, potentially shortening the motor’s lifespan.

- Mechanical stress: On motor components, leading to premature wear and tear.

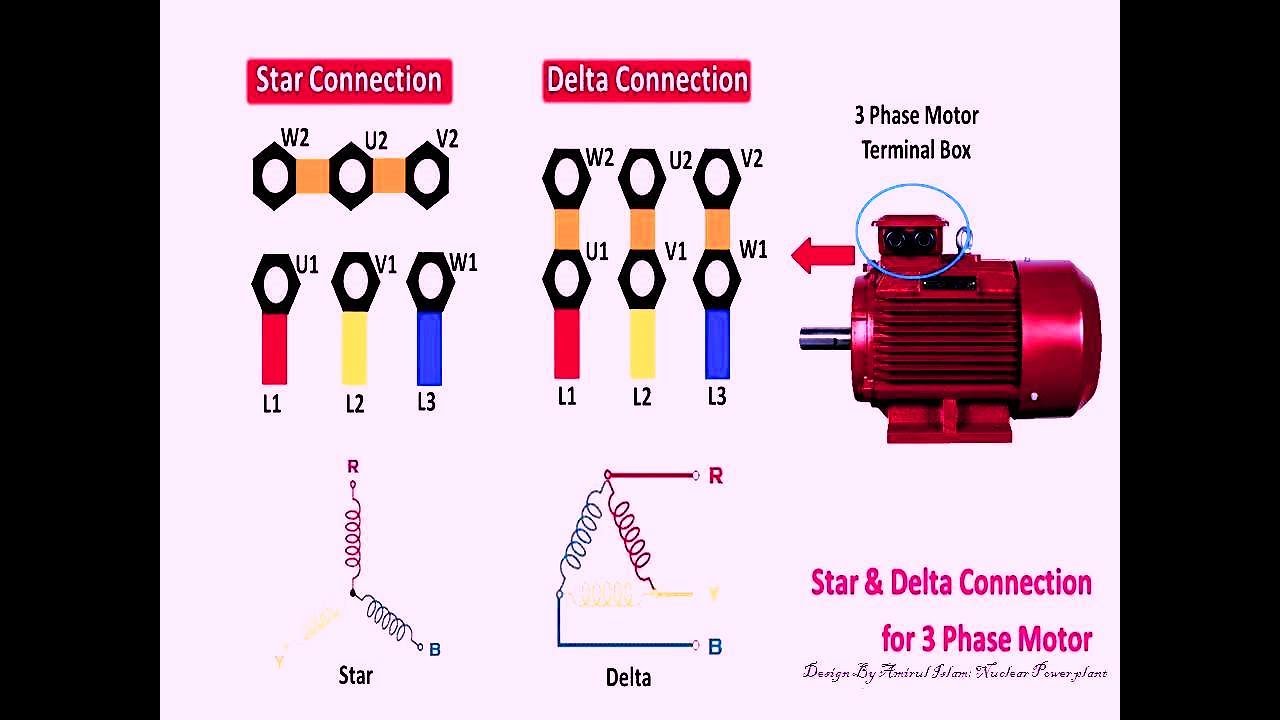

The star-delta starter addresses these issues by initially connecting the motor windings in a star (Y) configuration during startup. Once the motor reaches a predetermined speed (typically around 75-80% of its rated speed), the connection switches to a delta (Δ) configuration for normal operation.

How the Star-Delta Connection Works: A Detailed Look

The star-delta starting method utilizes a set of contactors and a timer to manage the switching between the star and delta configurations. Here’s a breakdown of the process:

Star Configuration (Starting Phase):

- The motor windings are connected in a star configuration. This means the voltage applied to each winding is reduced to 1/√3 (approximately 58%) of the line voltage.

- The starting current is significantly reduced, typically to about one-third of the delta starting current.

- The motor starts with lower torque.

Transition Phase:

- After a set time, the timer activates, and the star connection is disconnected.

- There’s a brief pause to allow the motor to coast.

- The delta connection is then established.

Delta Configuration (Running Phase):

- The motor windings are reconfigured in a delta connection.

- The full line voltage is applied to each winding.

- The motor operates at its rated voltage and torque.

Benefits of Using a Star-Delta Starter

The star-delta starter offers a compelling range of advantages, making it a popular choice for many motor applications:

- Reduced Inrush Current: The primary benefit is the significant reduction in starting current, mitigating voltage dips and protecting the motor and power supply.

- Lower Starting Torque: While this is a disadvantage in some applications, the lower starting torque is often acceptable and even beneficial for lightly loaded applications like fans and pumps, minimizing mechanical stress.

- Extended Motor Lifespan: Reduced inrush current and lower operating temperatures contribute to increased motor longevity.

- Energy Savings: By reducing inrush current and associated power fluctuations, the star-delta starter contributes to overall energy efficiency.

- Cost-Effective Solution: Compared to other starting methods, like soft starters or variable frequency drives (VFDs), the star-delta starter is a relatively simple and cost-effective solution, especially for applications where precise speed control isn’t essential.

Applications of Star-Delta Starters

The star-delta starter is suitable for a wide variety of applications. The key is to consider the motor’s starting torque requirements and the load characteristics. Some common applications include:

- Pumps: Water pumps, sewage pumps, and other pumping systems.

- Fans and Blowers: Industrial fans, ventilation systems, and air handling units.

- Conveyors: Belt conveyors and other material handling systems.

- Compressors: Air compressors used in various industrial settings.

- Machine Tools: Certain machine tools with less demanding starting torque requirements.

Factors to Consider When Implementing a Star-Delta Starter

While the star-delta connection offers many benefits, it’s essential to consider certain limitations:

- Reduced Starting Torque: The starting torque is about one-third of the delta starting torque. This may be insufficient for applications requiring high starting torque.

- Transition Torque Dip: The transition from star to delta can result in a brief torque dip, which could potentially cause the motor to stall if the load is too heavy.

- Not Suitable for All Motors: The motor must be designed for star-delta starting, with six accessible winding terminals.

Conclusion: Power Savings with Star-Delta

The star-delta connection is a valuable technique for optimizing the operation of 3-phase motors. By reducing inrush current, it minimizes voltage dips, protects equipment, and contributes to significant power savings. While not a universal solution, its cost-effectiveness and effectiveness make it a compelling choice for a wide range of applications. Properly implemented, a star-delta starter can significantly extend motor lifespan and reduce operational costs, making it a smart investment for energy-conscious businesses.

FAQs: Frequently Asked Questions

1. What is the main difference between star and delta connections?

The primary difference lies in the voltage applied to the motor windings. In a star connection, the voltage per winding is lower, resulting in reduced starting current and torque. In a delta connection, the full line voltage is applied to each winding, providing higher torque during normal operation.

2. When should I use a star-delta starter?

You should consider a star-delta starter when the motor’s load doesn’t require very high starting torque, and when reducing inrush current is critical to protect the motor and power supply. Typical applications include pumps, fans, and conveyors.

3. What type of motor is needed for a star-delta starter?

The motor must be designed for star-delta starting. This usually means it has six accessible winding terminals, allowing for the necessary connections.

4. What are the advantages of using a soft starter over a star-delta starter?

Soft starters provide smoother acceleration and deceleration, and often offer adjustable starting and stopping characteristics. They can also provide more precise control over the motor’s speed, which star-delta starters cannot. Soft starters are often a better choice for applications with frequent starts and stops or with sensitive loads.

5. Can I convert an existing motor to use a star-delta starter?

If the motor is designed for star-delta starting and has the necessary six terminals, then yes. However, the motor’s nameplate must be checked to confirm the proper winding connections. If the motor only has three terminals, then it cannot be used with a star-delta starter. Consulting a qualified electrician is highly recommended.