Aluminum Melting Furnace Schematic: A Guide for Hobbyists and Pros

Aluminum melting furnaces are essential for anyone involved in metal casting, from hobbyists creating small sculptures to professionals producing intricate parts. Understanding the underlying principles of these furnaces, including their schematics, is crucial for safe and effective operation. This guide provides a comprehensive overview of aluminum melting furnace schematics, catering to both beginners and experienced users. We’ll delve into the core components, design considerations, and safety aspects, equipping you with the knowledge to build, maintain, and utilize these furnaces effectively.

Understanding the Purpose and Importance of a Furnace Schematic

A furnace schematic acts as a blueprint, illustrating the arrangement and connections of all the components within an aluminum melting furnace. It’s the roadmap for understanding how the furnace works and how its different parts interact. Having a clear schematic is vital for:

- Construction: Guiding the assembly process, ensuring correct placement and connections.

- Troubleshooting: Identifying the source of malfunctions by tracing the flow of power, heat, and materials.

- Maintenance: Facilitating repairs and replacements, allowing for efficient upkeep.

- Customization: Enabling modifications and upgrades to improve performance or add features.

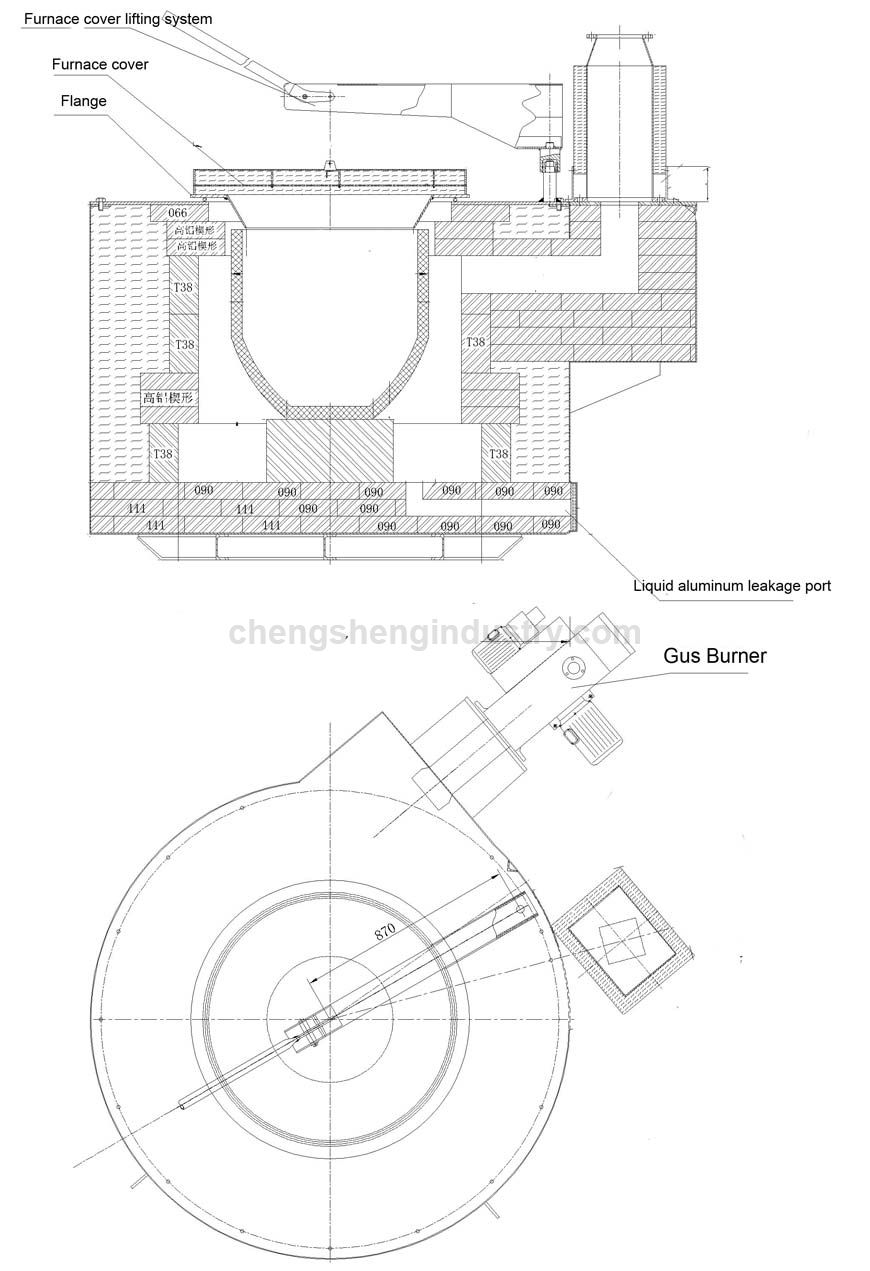

Key Components of an Aluminum Melting Furnace and Their Schematic Representation

The schematic for an aluminum melting furnace typically encompasses the following core components:

- The Crucible: The container that holds the aluminum during melting. The schematic will show its position within the furnace and its relationship to the heating element.

- The Heating Element: This is the heart of the furnace, generating the heat required to melt the aluminum. Common types include:

- Resistance Heaters: Often depicted as coils or wires, showing their wiring configuration (series or parallel).

- Propane/Gas Burners: Shown with fuel lines, burner nozzles, and air intake systems.

- Insulation: Crucial for retaining heat and protecting the outer shell. Schematics will illustrate the placement and layering of insulation materials, such as ceramic fiber or firebrick.

- The Furnace Shell: The outer structure that houses all the components. The schematic depicts its shape, dimensions, and materials.

- Power Supply/Fuel System: This details the source of energy for the furnace.

- Electrical Furnaces: Show the wiring, switches, transformers, and safety devices (fuses, circuit breakers).

- Gas-Fired Furnaces: Illustrate the gas lines, regulators, and safety shut-off valves.

- Temperature Control System (Optional): Sophisticated furnaces may include temperature sensors (thermocouples), controllers, and display units. The schematic will show the connections and placement of these components.

- Safety Features: Essential elements like ventilation systems (for fumes), protective eyewear, and gloves are typically illustrated within the context of the overall system.

Schematic Design Considerations: Hobbyist vs. Professional

The complexity of a furnace schematic can vary greatly depending on the intended use and the user’s experience level.

- Hobbyist Furnaces:

- Often simpler designs, focusing on ease of construction and basic functionality.

- Schematics might be hand-drawn or use simplified diagrams.

- Emphasis on readily available components and cost-effectiveness.

- Professional Furnaces:

- More complex designs, incorporating advanced features like temperature control and automated systems.

- Schematics are typically created using CAD (Computer-Aided Design) software, providing detailed dimensions, specifications, and component information.

- Focus on efficiency, durability, and safety, often meeting industry standards.

Building Your Own Aluminum Melting Furnace: Schematic Resources and Tips

- Online Forums and Communities: Utilize online forums and communities dedicated to metal casting and furnace building. These resources often provide schematics, build logs, and expert advice.

- DIY Guides and Tutorials: Numerous online guides and tutorials walk you through the construction process, often including detailed schematics.

- Component Selection: Choose components based on your budget, experience, and intended use. Consider factors such as temperature ratings, power requirements, and safety certifications.

- Safety First: Always prioritize safety. Wear appropriate personal protective equipment (PPE), work in a well-ventilated area, and never leave a furnace unattended while it’s operating.

- Start Simple: If you’re a beginner, start with a simpler design and gradually increase complexity as your skills and knowledge grow.

Safety Precautions When Working with Furnace Schematics

- Electrical Safety: Always disconnect the power supply before working on electrical components. Ensure all wiring is properly insulated and grounded.

- Gas Safety: When working with gas-fired furnaces, be meticulous about gas line connections and ensure proper ventilation to prevent the buildup of dangerous fumes.

- Material Handling: Handle molten aluminum with extreme care. Always use appropriate protective gear, including heat-resistant gloves, face shields, and aprons.

- Review the Schematic Thoroughly: Before starting any work, carefully review the schematic and understand the function of each component.

- Double-Check Connections: Verify all electrical and fuel connections before operating the furnace.

Maintaining and Troubleshooting Your Furnace Based on the Schematic

- Regular Inspections: Conduct regular inspections of all components, referring to your schematic to identify and address potential problems.

- Component Replacement: Replace worn or damaged components promptly, consulting the schematic for proper specifications.

- Troubleshooting Guide: Use the schematic to trace the flow of power, heat, or fuel when troubleshooting malfunctions.

- Documentation: Keep a log of any modifications or repairs performed on your furnace, updating the schematic as needed.

Conclusion

Understanding and utilizing aluminum melting furnace schematics is essential for anyone working with molten metals. Whether you’re a hobbyist or a professional, a well-designed and accurately interpreted schematic is your key to building, operating, maintaining, and troubleshooting your furnace safely and efficiently. By following the guidelines and tips outlined in this article, you can confidently navigate the world of furnace schematics and enhance your metal casting endeavors.

Frequently Asked Questions (FAQs)

What software is commonly used to create furnace schematics?

- CAD (Computer-Aided Design) software is widely used for professional-grade schematics. For simpler designs, hand-drawn diagrams or free online drawing tools can be sufficient.

How can I find schematics for different types of aluminum melting furnaces?

- Online forums, DIY websites, and manufacturer documentation are excellent resources. Search terms like “aluminum melting furnace schematic,” “gas-fired furnace schematic,” or “DIY furnace build” can yield valuable results.

What are the common causes of furnace malfunctions?

- Common causes include overheating, faulty heating elements, insulation failure, incorrect wiring, and fuel supply issues. The schematic helps you diagnose the specific problem.

What safety features should be incorporated into an aluminum melting furnace?

- Essential safety features include proper ventilation, over-temperature protection, emergency shut-off valves (for gas furnaces), and appropriate PPE.

Can I modify an existing furnace based on its schematic?

- Yes, but it’s crucial to fully understand the implications of any modifications. Always consult the schematic, and ensure any changes comply with safety regulations and are compatible with the furnace’s existing components.